New Battery Technology Could Help Achieving Environmental Targets

Posted on: in Blog

Introduction

To date, Lithium-Ion Batteries (LIB) have been the technology of choice for electric-powered transportation. One of the primary motivations for developing Electric Vehicles (EV) was, and remains, lowering of greenhouse gas emissions. Yet the environmental gains have been limited. Solid State Batteries (SSB), a post-LIB technology, with enhanced safety and performance compared to LIB, could also reduce global emissions due to:

- Less complex battery packs with fewer parts

- Lighter vehicles with higher driving efficiency

- Lower battery cooling requirement during charging

Working Towards Net Zero

Transportation is the largest source of global greenhouse gas emissions, making it a key challenge in meeting climate targets set by the Paris Agreement, including limiting global average temperature increase to below 1.5°C. Despite commitments at COP summits, progress remains slow, and achieving net-zero emissions by 2050 seems increasingly difficult. While the development of electric vehicles (EV) has been an obvious solution to reducing greenhouse gas emissions, recent adoption rates have slowed due to factors including policy shifts, high costs, insufficient infrastructure and continued concerns about battery longevity, charging speed and safety. In brief, drivers and EV manufacturers always strive for a better battery, but does a better battery also mean a more environmentally friendly battery?

Better Batteries

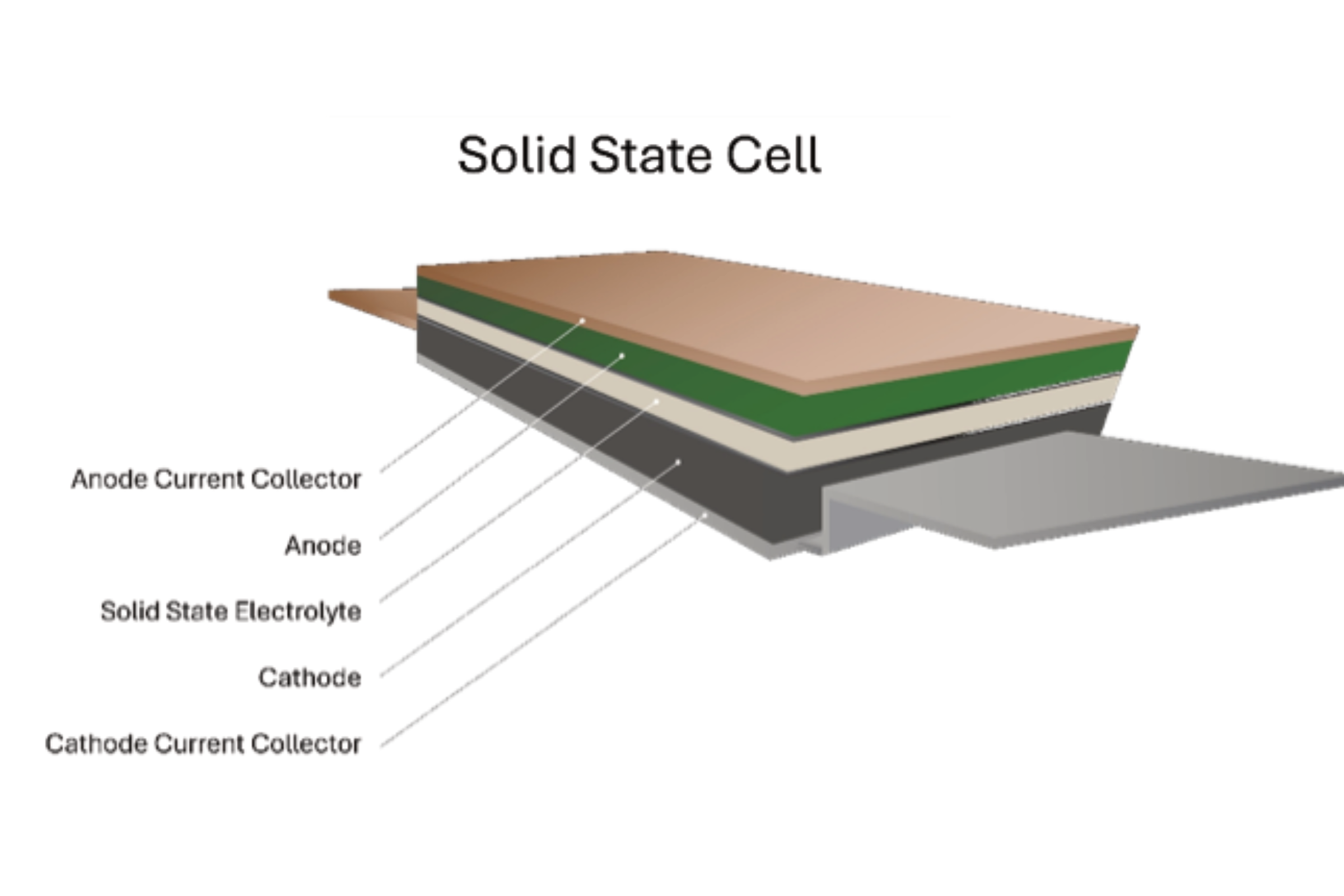

SSB replace the liquid electrolyte in LIB with non-liquid components. SSB can match, and even exceed the performance of the best LIB cells while offering greater safety. This combination of performance and safety could enable a simplification of the cooling system in the battery pack and removal of protection-related components, resulting in lighter, more efficient vehicles with longer range, higher power and lower cost. When SSB reach the market, will they improve on the reduced global warming impact of LIB?

Battery Pack Modelling

To find out, SSB developers Ilika Technologies and battery experts Balance Batteries Ltd (Balance Batteries) collaborated in modelling an hypothetical battery pack incorporating SSB rather than their current LIB. The Hyundai Ioniq 5, an electric SUV, was used as the baseline for modelling the pack. The pack’s weight, safety features, and design simplifications were analysed, assuming the SSB cells would replace the current LIB cells. Thanks to their superior features, SSB were found to offer several advantages, including faster charging (12 minutes versus 18 minutes for LIB) and lighter weight (reducing the pack weight by 100 kg – or adding further cells back in to improve range). The model also suggests significant cost reductions once SSB are in production, including a £2.5k reduction in materials and a 3% energy consumption improvement. What does this mean in terms of greenhouse gas emissions?

Life Cycle Analysis

A Life Cycle Analysis (LCA) of the hypothetical SSB pack was conducted. A LCA is a method used to assess the environmental impact of a product or process from its creation to disposal. It evaluates factors like resource extraction, production, use, and end-of-life, helping to identify areas for sustainability improvements and reducing overall environmental impact. Publicly available data and open-source software were used in the LCA. These programs calculate CO2e, or carbon dioxide equivalent, a unit of measurement that standardizes the climate impact of various greenhouse gases. Since greenhouse gas emissions vary depending on the source of electricity (fossils fuels, renewable energy or a mix of both), the production and usage of the SSB vehicle was located in Europe, which has a mix of 60% fossil fuel vs 40% renewable energy. The three questions asked were:

- Fewer battery parts: Since the SSB pack contains fewer components, can the reduction in emissions be calculated, which resides from not manufacturing these parts? When Balance Batteries compared the current battery pack weight for Hyundai Ioniq 5 with one including SSB, they found: 46.8 kg less weight due to increased cell-level energy density; 26 kg less weight due the replacement of intra-cell foam material with a thinner solid cell carrier; 6.6 kg less weight from removing thermal barrier materials and venting parts; up to 15.8 kg less weight (twice) from thinning down anti-intrusion beams. By not producing these non-essential components, a total of 750 kg CO2e could be removed per pack.

- Higher driving efficiency: Since the SSB vehicle is lighter and therefore more energy efficient, how does this translate in terms of global warming impact? Weight reduction in less complex packs has a real impact on the driving experience. Higher accelerating power would be available to a lighter vehicle for the same energy. Less tyre wear could take place during the life of the lighter vehicle. Using the Worldwide Harmonised Light Vehicle Test Procedure (WLTP), Balance Batteries modelled that the baseline (LIB) vehicle used 185.8 Wh/km and the SSB vehicle 180.1 Wh/km. Of course, there are no tailpipe emissions from an EV, but for a given distance, less energy is used that will not need to be recharged. This efficiency gain represents a reduction of 1.4 g CO2e per km driven. Considering that a Hyundai Ioniq 5 offers a range of up to 354 miles, and assuming that the vehicle is charged once a week for 10 years, this represents 420 fewer kg of CO2e emitted in the atmosphere over the lifetime of the vehicle.

- Reduced cooling during fast charges: Since SSB can charge faster, thanks to their high resilience against heating up, they will not need to be cooled as much as LIB: how does this energy gain translate into CO2e reductions? It was assumed here that up to 10% of the energy used to recharge the battery pack was “wasted” to simply keep the batteries cool during charging. This represents a loss of 2.1 kg CO2e per fast charge. Assuming that fast charges happen only once per month, the SSB vehicle would have emitted 252 fewer kg of greenhouse gases in a 10-year period.

Conclusions

Although Ilika’s SSB cells are not yet available commercially and their specifications may change with further development, modelling a hypothetical SSB pack showed some clear potential benefits in terms of reducing the global warming impact of such a vehicle. A medium-sized EV sold in 2025 is estimated to emit a total of 10.7 tons of CO2e: around 40% of EV carbon emissions are generated from usage/charging followed by vehicle production (32%), battery manufacturing (25%) and recycling (3%). Replacing the LIB cells with SSB cells would save 1.4t CO2e per vehicle, or a reduction of 13%, over the vehicle life cycle. This gives hope that new battery technologies will indeed help the world reach its environmental targets.